At NDI Consultants, our capabilities include:

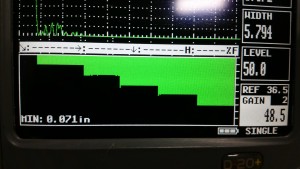

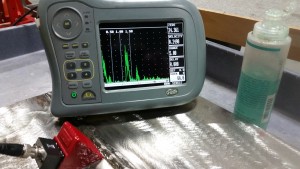

Ultrasonic Thickness & Corrosion Loss Inspection: Piping or Pressure Vessel, NDI has A-Scan & B-Scan equipment to meet your inspection needs.

Ultrasonic Sheer Wave Weld Inspection: NDI has experienced ASTM, ASME, AWS D1.1 (Structural Steel), D1.2 (Aluminum), D1.5 (Bridge), D1.6 (Stainless Steel), D14 (Cranes), D17 (Aerospace).

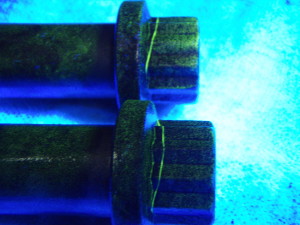

Magnetic Particle Inspection, Wet Florescent: NDI’s capabilities include the “wet florescent method” ideally suited for aerospace manufacturing and other safety critical applications. The common applied codes are MIL-STD-1907, ASTM E1444, and ASTM E709.

Magnetic Particle Inspection, Wet Visible: In the “Wet Visible” technique, a white contrasting coating is sprayed onto the test specimen. Next, an oil based black spray is applied over the white base and the surface evaluated for cracks or other defects. This technique is excellent for un-finished fabricated parts such as weldments. Typical applied codes are: MIL-STD-1097, ASTM E1444, & ASTM E709

Magnetic Particle Inspection, Dry Visible:

Liquid Penetrant Inspection: Florescent: Type I, Methods A,B,C, & D, Sensitivity Level 1/2, 1, 2, 3, & 4, Form A, B, C, D, E, & F:

Liquid Penetrant Inspection: Visible Type II

Eddy Current: High Frequency, Low Frequency, Open Hole, Heat Exchanger limited application informational only.

X-Ray: